Footwear Inspection Expertise - Footwear Quality Control

HOW TO PERFORM FOOTWEAR INSPECTION

Footwear Inspection – Footwear Quality Control Services in China and Asia

Effective footwear inspection extends beyond visual assessment. It encompasses a comprehensive evaluation of various factors that contribute to the overall quality, safety, and performance of footwear products. Footwear quality control ensures that shoes, boots, and other footwear items meet industry standards, are safe for consumers, and provide comfort and durability.

Tetra Inspection, a global leader in inspection services, offers a team of highly experienced inspectors with expertise in footwear quality control. Our inspection process goes beyond surface-level checks and employs advanced tools and techniques to assess various aspects of footwear, including materials, construction, fit, and compliance with industry regulations.

Ensure your footwear products meet the highest standards of quality and safety – book a comprehensive footwear inspection with Tetra Inspection today.

FOOTWEAR QUALITY CONTROL

The Importance Of Footwear Inspection

Footwear inspection is a critical aspect of quality control in the footwear industry. It ensures that footwear products meet the necessary standards for comfort, durability, safety, and performance. Quality footwear not only provides comfort but also contributes to overall foot health, preventing discomfort, injuries, and potential hazards. Here are five vital aspects to consider during a footwear inspection:

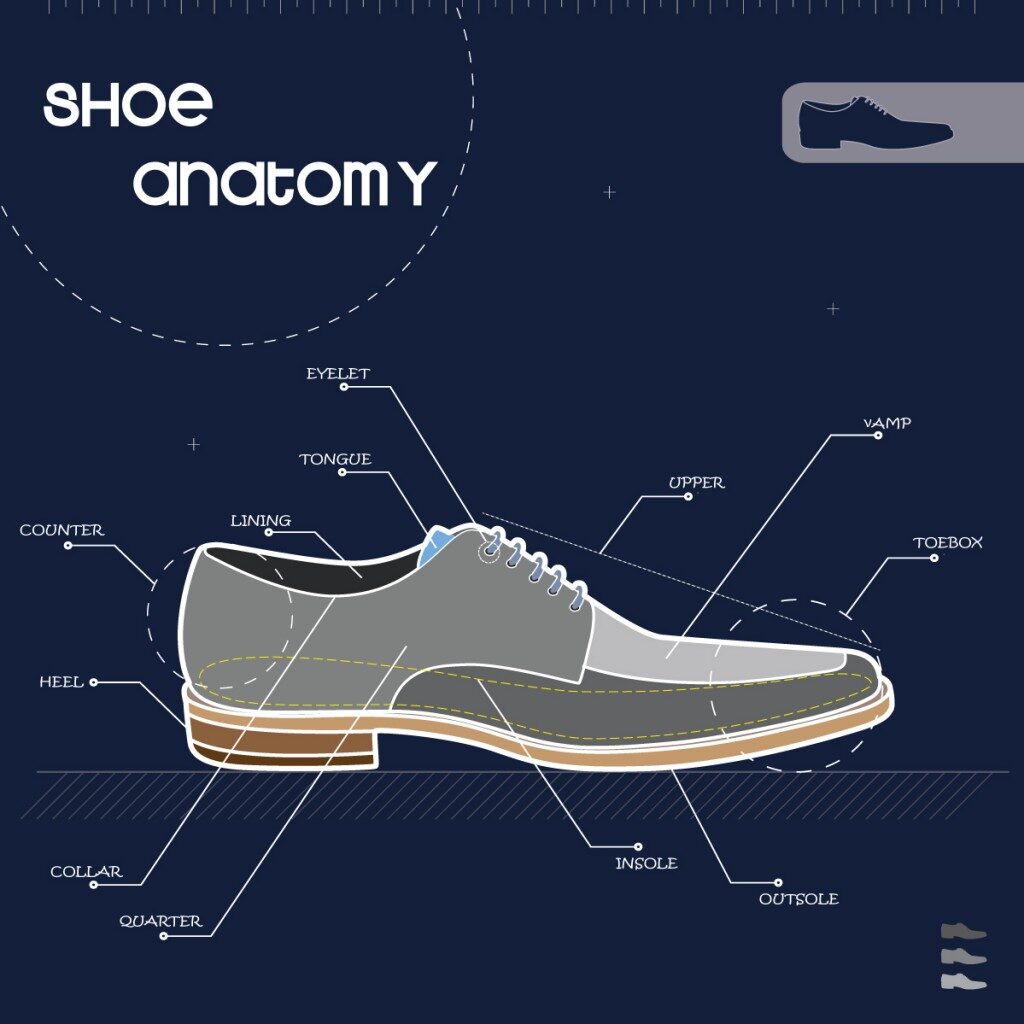

- Materials and Construction Assessment: Footwear should be constructed with high-quality materials to ensure durability and comfort. Inspectors assess the quality of materials used for the upper, sole, lining, and insoles. They also scrutinize stitching, adhesives, and fasteners to ensure they meet quality standards.

- Fit and Sizing test: Proper fit and sizing are crucial for comfort and functionality. Inspectors verify that the footwear adheres to the specified sizing standards and that the fit is comfortable for wearers.

- Performance and Safety: Footwear must perform well and offer protection. Inspections involve testing slip resistance, abrasion resistance, and puncture resistance. Safety features, such as steel toes for work boots, are also assessed for compliance.

- Comfort and Support: Comfort is a key factor in the quality of footwear. Inspectors assess cushioning, arch support, and overall comfort features to ensure that the footwear provides a comfortable experience for users.

- Aesthetics and Finish: Beyond functionality, the appearance of footwear is essential. Inspectors check for any cosmetic defects, color consistency, and proper finishing to ensure that the footwear meets aesthetic standards.

Different Types Of Footwear Products

Footwear products have evolved beyond basic foot protection, now serving as both fashion statements and specialized equipment. This transformation has led to innovations, patents, and advanced technologies in the industry, emphasizing the importance of thorough footwear inspection for buyers and importers.

Key Types of Footwear Products We Inspect:

- Boots

- Shoes

- Sandals

- Slippers

- Ice Skates

- Flip-flops

- Ballet Flats

- Work Shoes

- Loafers

- Sport Shoes

- Sneakers

- Swim Fins

- Espadrilles

- Ballerina Shoes

Key Elements Of Footwear Inspection

Footwear inspection is a comprehensive evaluation of various elements to ensure the quality, safety, and compliance of footwear products. Here are the key elements typically evaluated during footwear quality control:

Material Quality Assessment: Inspectors examine the quality of materials used in the footwear, including leather, synthetic materials, textiles, and hardware such as eyelets and buckles.

- Construction Integrity: The construction of the footwear is assessed, including stitching, glue bonding, and reinforcement at stress points

- Sole and Outsole Inspection: The sole and outsole are examined for wear resistance, flexibility, and slip resistance. Inspectors also check for proper sole attachment.

- Fit and Sizing Verification: Sizing accuracy is verified, and inspectors assess whether the footwear provides a comfortable fit according to industry standards.

- Performance Testing: Testing includes slip resistance, water resistance, and other performance-related assessments based on the footwear’s intended use.

- Comfort Evaluation: Cushioning, arch support, and overall comfort features are evaluated to ensure user comfort during extended wear.

- Aesthetics: The appearance of the footwear is inspected for cosmetic defects, color consistency, and proper finishing.

- Labeling and Packaging: Inspectors verify that footwear is correctly labeled with size, material composition, care instructions, and other relevant information. Packaging is also inspected for protection during transportation.

VITAL STEP IN THE MANUFACTURING

The Footwear Quality Control Process

The footwear quality control process is essential for manufacturers and distributors to ensure that footwear products meet established quality standards and safety regulations. It involves a systematic examination of various elements of footwear, from materials and construction to performance and labeling.

Here are the stages of the footwear quality control process:

Design Review: Our expert inspectors work closely with manufacturers to meticulously review design specifications. This includes assessing materials, construction methods, and safety features to ensure they align with quality standards.

Footwear Materials Verification: We conduct a thorough examination of individual components, such as upper materials, sole materials, and hardware, ensuring they not only meet but exceed quality standards for durability and performance.

Factory Capabilities Evaluation: Our team evaluates the manufacturing facility’s capabilities, machinery, and workforce to ensure they are equipped to meet production demands while upholding stringent product quality standards.

Workmanship Assessment: We provide continuous oversight during the production process, meticulously monitoring the assembly, stitching, bonding, and overall construction of footwear. This vigilance ensures that workmanship defects are identified and rectified promptly.

Material Usage Check: Our inspectors verify that the correct materials are being used in strict accordance with design specifications, maintaining the integrity of your footwear products.

Performance Testing: We conduct rigorous performance test During Production Inspection in order to detect and address any issues early in the manufacturing process, ensuring the final product meets your exacting standards.

Final Random Inspection: Our comprehensive approach involves random sampling of finished footwear products. This ensures that each item conforms to the approved design and maintains consistent quality across the entire production batch.

Performance Testing: We rigorously verify key performance features such as slip resistance, comfort, and sizing, guaranteeing that your footwear products are not only stylish but also safe and functional.

Labeling and Packaging Inspection: Our inspectors meticulously examine labeling accuracy and packaging to ensure that your footwear is not only well-protected during transportation but also correctly labeled, complying with all relevant regulations. This meticulous attention to detail is our commitment to delivering excellence in every aspect of the inspection process.

How shoe qc tests are performed

Main Tests Performed During A Footwear Inspection

During a footwear inspection, a battery of tests is conducted to ensure quality and safety. These tests cover slip resistance, material strength, size fitting, and endurance, etc.

- Carton drop test.

- Slip resistance.

- Sole bonding test.

- Material strength check.

- Humidity content check.

- Symmetry check.

- Endurance check.

- Symmetry check.

- Sharp component check.

- Mold contamination check.

- Size fitting test.

- Measurement check.

- Rub test.

- Odor check.

- Barcode scanning.

- Weight check

Applicable Standards For Footwear Quality Control

Adhering to industry and international standards is crucial for ensuring that footwear products meet quality and safety requirements. Here are some key standards applicable to footwear quality control:

- ASTM F2412 and F2413: These ASTM standards cover the performance requirements for safety footwear, including impact resistance and electrical hazard protection.

- ISO 20345 and ISO 20347: ISO standards for safety footwear and occupational footwear specify requirements for various safety and performance aspects, including slip resistance and comfort.

- EN ISO 20345 and EN ISO 20347: European standards that define safety and occupational footwear requirements for the European market.

- ANSI Z41: ANSI standards for safety footwear, covering impact and compression resistance, electrical hazard protection, and more.

- AATCC and SATRA: Industry organizations that provide testing and performance standards for footwear, including wear testing and slip resistance

How Tetra Inspection Can Help With Footwear Inspection Services

Comprehensive Inspections

Tetra Inspection conducts thorough pre-production, in-line, and final random inspections to identify and rectify any issues, ensuring that your footwear meets the highest quality standards.

Customized Solutions

We understand that every footwear product is unique. Our inspection solutions are customizable to align with your specific requirements, whether they involve intricate designs, specialized materials, or diverse product lines.

Experienced Inspectors

Our inspectors possess extensive experience and expertise in footwear quality control. They pay meticulous attention to detail, evaluating all aspects of your footwear products, from materials to performance.

Prompt Reporting (24 Hours)

Count on Tetra Inspection to deliver timely and detailed inspection reports within 24 hours. Our reports provide a comprehensive overview of inspection findings, enabling you to take swift action to address any issues.

Schedule Your Footwear Inspection Today

Count on our team of seasoned experts to conduct meticulous footwear inspection, minimizing risks, and ensuring strict compliance with international standards.

BLOG

Related Articles

shipment, minimizing risks and ensuring compliance with international standards.