Consumer Electronics Inspection - Consumer Electronics Quality Control Services

Electronics Products Inspection

Consumer Electronics Inspection – Electronic Quality Control

At Tetra Inspection, we are trusted by global companies for comprehensive consumer electronics inspection and quality control services.

With our extensive expertise and a commitment to upholding the highest industry standards, we ensure that your consumer electronics products meet the stringent requirements for safety, functionality, and performance.

From pre-production assessments to final random inspections, our dedicated team of experienced inspectors is here to ensure that your electronics products exceed customer expectations.

To ensure your consumer electronics products are reliable, safe and compliant, book an inspection today!

CONSUMER ELECTRONICS INSPECTION

Why Consumer Electronics Inspection Matters

The consumer electronics market is highly competitive, yet the product quality could be more sustainable. Consumer electronics products, ranging from smartphones and tablets to smart home devices and audio equipment, are essential aspects of modern life. Ensuring that these products are safe, reliable, and compliant is paramount to building customer trust and maintaining a competitive edge.

Here’s why consumer electronics inspection matters:

Product Safety and Compliance:

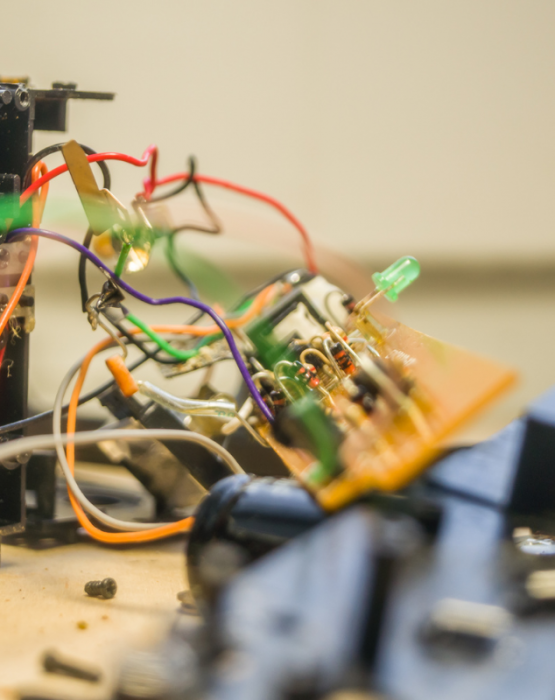

Consumer electronics products often involve intricate electrical components and batteries. Ensuring proper assembly, wiring, and insulation is critical to preventing safety hazards such as electrical malfunctions, short circuits, and even fires. Our inspections verify that your products adhere to safety standards and regulations, safeguarding both consumers and your brand reputation.

Durability and Longevity:

Consumer electronics products are meant to last. Through rigorous inspections, we assess the quality of materials, construction, and components to ensure that your products withstand the test of time, minimizing returns and warranty claims.

Customer Satisfaction:

When consumers invest in electronic products, they expect reliable performance and value for their money. By conducting thorough quality control, you’re not only meeting their expectations but also cultivating brand loyalty and positive reviews.

Functionality and Performance:

Whether it’s a smartphone with advanced features or a smart home device with connectivity capabilities, consumers expect their electronics products to perform flawlessly. Our inspections include functional testing to ensure that every aspect of your product works as intended, delivering a seamless and satisfying user experience.

Energy Efficiency:

As energy efficiency becomes increasingly important, our inspections verify that your electronics products meet or exceed industry standards for power consumption. Energy-efficient products not only save consumers money but also contribute to sustainability efforts.

consumer electronics products TESTING

Common Types Of Defects In Consumer Electronics

Tetra Inspection offers comprehensive consumer electronics inspection services to identify various defects and issues that can compromise the safety, functionality, and quality of electronic products. Here are some examples of defects that our experienced inspectors may find during the inspection process:

Assembly Defects:

- Loose or improperly secured components: Components like microchips, connectors, or batteries may not be securely attached to the PCB (Printed Circuit Board), leading to potential functionality issues.

- Soldering defects: Poor soldering can result in weak electrical connections, leading to intermittent or complete failures in the device’s operation.

Battery and Power Issues:

- Battery defects: Battery-related problems such as overcharging, undercharging, or inadequate battery life can be identified during inspection.

- Power supply issues: Inadequate power management or charging circuitry can lead to overheating or device damage.

Safety and Compliance Issues:

- Insufficient insulation: Lack of proper insulation in electrical components can pose electrical safety hazards.

- Non-compliance with regulatory standards: Failure to meet safety and environmental regulations, such as RoHS requirements, can lead to legal and reputational issues.

Functional Defects:

- Non-responsive buttons or touchscreens: Inoperable buttons or touchscreens can render the device unusable or frustrating for consumers.

- Sensor calibration issues: Sensors (e.g., proximity sensors, accelerometers) may not function correctly, affecting features like auto-brightness adjustment or device orientation.

Build Quality and Cosmetic Defects:

- Scratches, dents, or cosmetic imperfections: Surface defects can affect the device’s aesthetics and overall customer satisfaction.

- Loose or misaligned components: Poor build quality can result in components not fitting together correctly.

Packaging and Documentation Errors:

- Incomplete or incorrect user manuals: Missing instructions or incorrect information can confuse users and result in suboptimal product experiences.

- Missing safety certifications: Lack of required safety certifications in the documentation can lead to legal complications.

VITAL STEPS IN THE Consumer Electronics Inspection process

The Consumer Electronics Inspection Process

The consumer electronics inspection process is a critical phase in the production and distribution of electronic devices, ensuring they meet stringent quality standards, performance expectations, and safety regulations. This process involves meticulous evaluation of various components and functionalities to identify defects, discrepancies, or issues that need correction before the products are released to the market.

Here’s a concise overview of the key stages in the consumer electronics inspection process:

Before manufacturing begins, a pre-production Inspection for Consumer Electronic takes place. Inspectors collaborate with manufacturers to review design specifications, verify materials, and confirm the production facility’s capability to produce high-quality electronics.

Material Verification: Inspectors examine and validate the quality of components that will be integrated into the electronic devices, including microchips, circuit boards, displays, batteries, and connectors.

Design Review: A thorough evaluation of design specifications is conducted to ensure they meet desired quality, functionality, and safety standards.

Production Capability Evaluation: Inspectors assess the manufacturing facility’s equipment, technology, and workforce to ascertain their ability to meet production demands while maintaining product excellence.

During manufacturing, in-line inspections occur at various stages to identify and address potential issues promptly.

Assembly Quality Check: Inspectors monitor the assembly process to detect any defects in soldering, component placement, or connections that could impact the device’s performance or reliability.

Functional Testing: Electronics undergo functional testing to verify that all features, such as buttons, touchscreens, sensors, and interfaces, operate correctly according to design specifications.

Quality Defect Identification: Inspectors identify and rectify defects, irregularities, or deviations from quality standards that may arise during production, ensuring that only flawless devices proceed to the next stages.

After manufacturing, a Pre-shipment Inspection is conducted before shipping the products.

Sampling Inspection: Inspectors randomly select units from the batch and subject them to comprehensive testing and examination to verify adherence to quality benchmarks and regulatory standards.

Performance Testing: The devices undergo performance testing to ensure they meet predetermined criteria, such as processing speed, battery life, connectivity, and audio-visual quality.

Packaging and Loading Oversight: Inspectors supervise the packaging process to ensure devices are adequately protected for transportation. They also oversee the loading of products onto shipping containers to prevent damage during transit.

Documentation Review: Inspectors verify that all necessary documentation, including user manuals, warranty information, and safety certifications, is included with each device.

Electronics Products Quality Standards

Applicable Standards For Consumer Electronics Quality Control

Several key standards govern consumer electronics quality control, ensuring that these devices are not only functional but also safe for users. Here are five of the most important standards applicable for consumer electronics quality control:

- International Electrotechnical Commission (IEC) 60950-1 Safety of Information Technology Equipment This standard sets safety requirements for various information technology equipment, including consumer electronics devices such as computers, smartphones, and peripherals. It addresses potential hazards related to electrical, mechanical, and thermal aspects of these products, ensuring user safety during normal operation and foreseeable misuse.

- Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU)Although not a single standard, the RoHS directive is a regulation that restricts the use of hazardous substances in electrical and electronic equipment. It limits the presence of substances like lead, mercury, and cadmium in consumer electronics products, promoting environmental protection and reducing health risks for both users and those involved in manufacturing.

- Federal Communications Commission (FCC) Part 15Radio Frequency Devices FCC Part 15 sets limits on the electromagnetic interference that electronic devices, including consumer electronics, can generate. This is crucial to ensure that these devices don’t interfere with other devices’ functionality, from Wi-Fi routers to medical equipment, maintaining reliable communication and operation.

- Energy Star ProgramThe Energy Star program is highly relevant for consumer electronics, particularly devices that consume energy. It sets energy efficiency criteria that encourage manufacturers to produce electronics that consume less energy during use, contributing to reduced energy bills and environmental impact.

- International Organization for Standardization (ISO) 9241-303 Ergonomics of Human-System Interaction – Part 303: Requirements for Electronic Visual Displays This ISO standard focuses on the ergonomic aspects of electronic visual displays, which are ubiquitous in consumer electronics like smartphones, tablets, and TVs. It ensures that displays are designed in a way that minimizes visual fatigue and discomfort, optimizing the user experience and preventing adverse health effects.

Why Choose Tetra Inspection For Consumer Electronics Inspection

Extensive Expertise

Our team of inspectors possesses extensive knowledge and experience in the consumer electronics industry, allowing us to provide accurate and thorough evaluations.

Customized Solutions

We understand that each company has unique quality criteria. Our inspection services can be flexible to meet your specific requirements, whether you’re dealing with complex designs or diverse materials.

Prompt & Transparent Reporting

We provide detailed inspection reports within 24 hours, giving you swift access to findings and enabling you to address any potential issues immediately.

Comprehensive Approach

Our inspection process covers all aspects of consumer electronics products, from safety and functionality to energy efficiency and compliance with industry standards.

Schedule Your Consumer Inspection Today

Count on our team of seasoned experts to conduct meticulous consumer electronics inspections, minimizing risks, and ensuring strict compliance with international standards.

BLOG

Related Articles

shipment, minimizing risks and ensuring compliance with international standards.