RoHS compliance, or the Restriction of Hazardous Substances Directive, is a set of regulations put in place by the European Union to protect human health and the environment from the harmful effects of certain hazardous substances. These regulations apply to all manufacturers and distributors of electronic and electrical equipment, and compliance is mandatory for any product sold in the EU. In this blog post, we will discuss what RoHS is, its compliance requirements, the impact of compliance, and how to ensure compliance in your manufacturing or distribution business.

Why is RoHS compliance important?

RoHS, or the Restriction of Hazardous Substances Directive, was first introduced in 2002 by the European Union. The directive bans the use of certain hazardous substances, including lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs), in the manufacturing of consumer electronics and electrical equipment. The goal of RoHS is to reduce the amount of hazardous waste generated by these products and to protect human health and the environment from the negative effects of these substances.

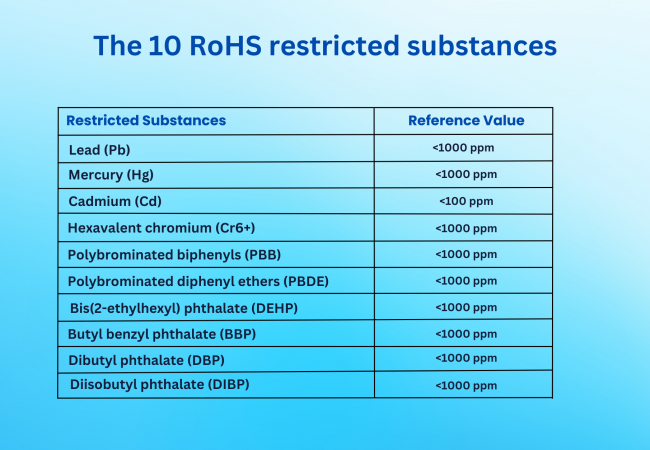

RoHS Compliance: 10 Restricted Substances

The RoHS Directive bans the use of these substances in electrical and electronic equipment, with some exemptions and exclusions. It applies to products placed on the EU market and is enforced through national legislation in EU member states.

The 10 restricted RoHS substances are:

Lead (Pb): <1000 ppm

Mercury (Hg): <1000 ppm

Cadmium (Cd): 100 ppm

Hexavalent chromium (Cr6+): <1000 ppm

Polybrominated biphenyls (PBB): <1000 ppm)

Polybrominated diphenyl ethers (PBDE): <1000 ppm

Bis(2-ethylhexyl) phthalate (DEHP): <1000 ppm

Butyl benzyl phthalate (BBP): <1000 ppm

Dibutyl phthalate (DBP): <1000 ppm

Diisobutyl phthalate (DIBP): <1000 ppm

How to Ensure RoHS Compliance

To ensure RoHS compliance, manufacturers and distributors should take the following steps:

- Identify and eliminate prohibited substances from their products and supply chain.

- Implement a system for documentation and record keeping to verify compliance with RoHS regulations.

- Seek assistance from compliance experts or certifying bodies for guidance and support.

- Stay up-to-date on any changes or updates to RoHS regulations, as they are subject to revision.

How Tetra Inspection can help you with RoHS compliance audit

If you need assistance with the RoHS compliance audit, Tetra Inspection is the perfect partner to help you through the process.

Our certified auditors can guide you through every step of the process including an initial assessment, developing a compliance plan, testing, and verifying your product is compliant with RoHS regulations.