What Is Grayscale? How To Use It?

What Is Grayscale?

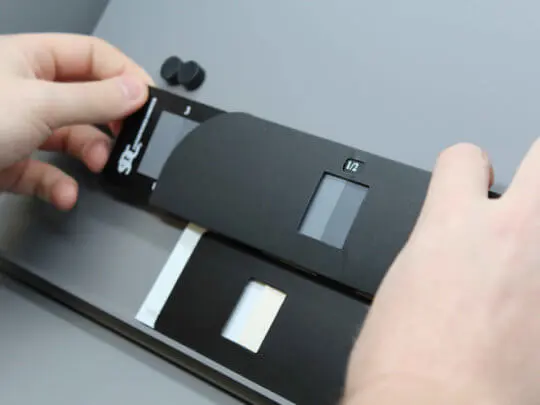

Grayscale is used for assessing the color shading in between products and the customer’s approval sample or among pieces in production. Grey scaling has grades 1-5 and increases by half of the grade (1, 1 1/2, 2, 2 1/2, and so on.) with 5 being the greatest. Generally speaking, many overseas clients can accept above grade 4, while some can accept the grades 3-4.

There are two types of Grayscale (Gray Scale)– one for evaluating ‘color modification’ and one for evaluating ‘staining’. The color change scale consists of nine sets of grey-coloured chips, from grades 1 to 5.

How to use Grayscale?

For color staining. It mainly is used for examining staining after rubbing with dry and wet white cotton cloths, in a professional lab. The employee usually attaches one white cotton cloth to the sample. Then, they will put them together into a washing maker and observe the outcome. An inspector usually cannot perform this test on-site given that the equipment and time are restricted. Rather, an inspector may carry out a rub test for color staining. To do this, the Inspector ought to prepare 2 pieces of white cotton material: one wet and the other dry. The garments quality inspector will rub the production sample 10 times with both with a force 9N( 1KG).

Nowadays, a lot of 3rd party inspection companies are increasing their inspectors’ skills and training on how to utilize special tools to examine product quality. For example, during a soft-goods or fabric inspection, the most essential tools that will be used are newton meters, metal detectors, barcode scanners, Pantone books, and so on. While all these tools are important, the only way to assess the color shades accurately during a textile quality inspections is the Grayscale.

Grayscale Expected Results:

- There needs to be no color transfer even worse than grade 4 on a Grayscale (between the initial white fabric and the colored one) after the dry test.

- There must be no color moved even worse than 3-4 on a Grayscale (in between the initial white fabric and the colored one) after the wet test.

- In order to get the most from your outcomes, the inspector must make certain to analyze the technique and outcome and discuss it with the factory plainly.

The factory must be able to help, such as by providing great quality 100% cotton white fabric and supplying excellent room lighting and conditions. In a textile inspection, the inspector’s experience is extremely essential when performing this test, so make certain to utilize a trustworthy Quality Control Company provider!

How to use Grayscale

so Customized Quality control services. The boy liked birds, but he was afraid of cats. Similarly, he did not like lions and tigers. Jonas promised to love, honor, and also obey his wife. Moreover, he will do all the cooking and cleaning while he studies at home. Furthermore, he is grateful that his new wife earns enough money to pay the bills. Harry ate six shrimp at dinner. Beautiful giraffes roam the savannah. Sue changed the flat tire. We are going to watch a movie tonight. I will clean the house every Saturday. so, Tom painted the entire house. The teacher always answers the students’ questions. Harry ate six shrimp at dinner. Beautiful giraffes roam the savannah. Sue changed the flat tire. We are going to watch a movie tonight. Mom read the novel in one day. I will clean the house every Saturday. Tom painted the entire house. The wedding planner is making all the reservations. The director will give you instructions. Ali is fat. saim is slim. Tahir is clever. Mom cooks food. I do Amazon FBA Inspection. Ali is bad. I go to school. Finally, I left my job. Eventually, I have passed the test. life is easy. And he does it. So he plays cricket.