China Inspection Company: How to Choose the Right One

What is an inspection company and what do they do

Quality control inspections are a process of measuring, testing, examining, or gauging against specific predetermined standards and regulations. A quality control Inspection company performs several types of tests at different levels of production and compares their findings with the standards to ensure that the quality of the product or service meets the required level set by the company, and customs authority. Deviations from these standards often result in defective products, which can lead to wasted time, materials, and other resources. By conducting quality control inspections, a China inspection company can help buyers avoid potential quality issues that could lead to the cost of quality rising exponentially and customer dissatisfaction.

How to choose the best China inspection company

Hiring reliable quality inspection services are essential for any brands or retailers manufacturing in China. Choosing the right one is critical to ensuring that your products meet all quality standards and meets all relevant regulatory requirements. Here are some tips on how to hire a third party inspection company in China that meets your quality assurance needs and ensures that you get the products you paid for:

Do your research:

Quality control issues are real and the cost of quality is expensive. So it’s important to do your homework before selecting reputable inspection companies in China. Read online reviews, and talk to other businesses that have used inspection services in the country.

Consider the experience and expertise of the inspection companies:

Another important factor to consider is the experience, expertise and range of services that the agency offers. A company specializing in quality control services should offer an Initial Production Check, During Production Inspection, Pre-shipment Inspection, and Container Loading Inspection, and auditing services such as Supplier Audit, complete Factory Audit, and complete Social Audit. Make sure to hire a quality inspection services company that has relevant experience and specialization in your product category so that they can make the best quality control judgments for the products you’re manufacturing.

Get quotes:

Once you’ve identified a few potential inspection companies, get in touch and request quotes. This will give you a better idea of pricing and help you compare different quality control service providers.

Ask for references:

Any reputable quality control services should be able to provide you with references from satisfied clients. Get in touch with these references and ask about their experience with the company. This will help you ensure that you’re getting the best value for your money.

Make your decision:

After considering all of the above factors, you should be in a good position to choose the right quality control partner for you.

The benefits of using a China inspection company

When it comes to quality control and quality assurance in China, it may not be feasible for your team to perform inspections on their own. Working with a professional QC services provider in China is the best way to get the job done more effectively and efficiently. Here are some of the benefits of using a reputable China-based quality control services provider:

Fresh and impartial perspective:

A third party inspection company can offer you a fresh perspective on the quality control standard and safety measures adopted by the manufacturers. Based on their unbiased report, you can uncover potential quality control issues that may otherwise go unnoticed.

Identify and mitigate risks:

An independent inspection company can safeguard your supply chain by identifying and mitigating the risk factors before they can cause serious harm. For instance, if your manufacturer uses poor quality materials for the consumer electronics items, a detailed inspection by the quality inspection companies can prevent accidents, injuries and potentially, a lawsuit.

They can save you time and money in the long run:

At every level of production, the cost of fixing quality issues costs 10 times more than the previous one. For example, if it costs 1 dollar to fix a quality issue at the During Production Check, the same thing will cost you 10 dollars to fix at the Pre shipment Inspection stage in case you missed it. By detecting the quality issues early, a third-party quality inspection company not only enables you to take corrective measures early on but saves your time and money down the line.

How quality inspections work:

1. On-site inspection:

An on-site inspection visit is the first step in the inspection procedure. The purpose of an on-site inspection visit is to verify that the products meet the required specification and to assess the packaging and labelling.

During an on-site inspection visit, a third-party auditor will:

• Verify that the products meet the required specification

• Assess the packaging and labelling

• Take photos or videos of the products and packaging

• Collect samples of the products

• Prepare a detailed report based on their findings

2. Quantity verification:

While verifying quantity, a quality inspections professional examines, weighs and verifies the quantity of finished goods in each carton that will be loaded in the container.

3. Conformity check:

Product conformity checks are important quality control measures that ensure that products meet all relevant safety, regulatory and quality standards. While checking the conformity of the product, a quality inspector compares the product against a set of requirements or specifications. If the product does not meet these standards, it may be rejected or recalled. Product conformity checks are essential to ensuring that only safe and high-quality products reach consumers.

4. Functional and Safety tests:

Quality inspectors conduct several functional tests to assess whether a product functions as expected. On the other hand, a safety test helps determine whether the product is safe for use.

5. Random Selection:

Random selection is a sampling technique where samples are chosen from the finished goods entirely at random. This technique is often used in quality inspection to ensure that products are up to standard. Using Acceptable Quality Level (AQL), the quality control inspector determines the acceptable number of defects in each batch. Based on their findings, they either accept or reject the batch.

6. Cosmetic and Workmanship check:

In this step, the inspector categorizes the defects into three categories based on their severity; Minor, Major or Critical. The products are either accepted or rejected depending on the agreement between the buyer and manufacturer.7

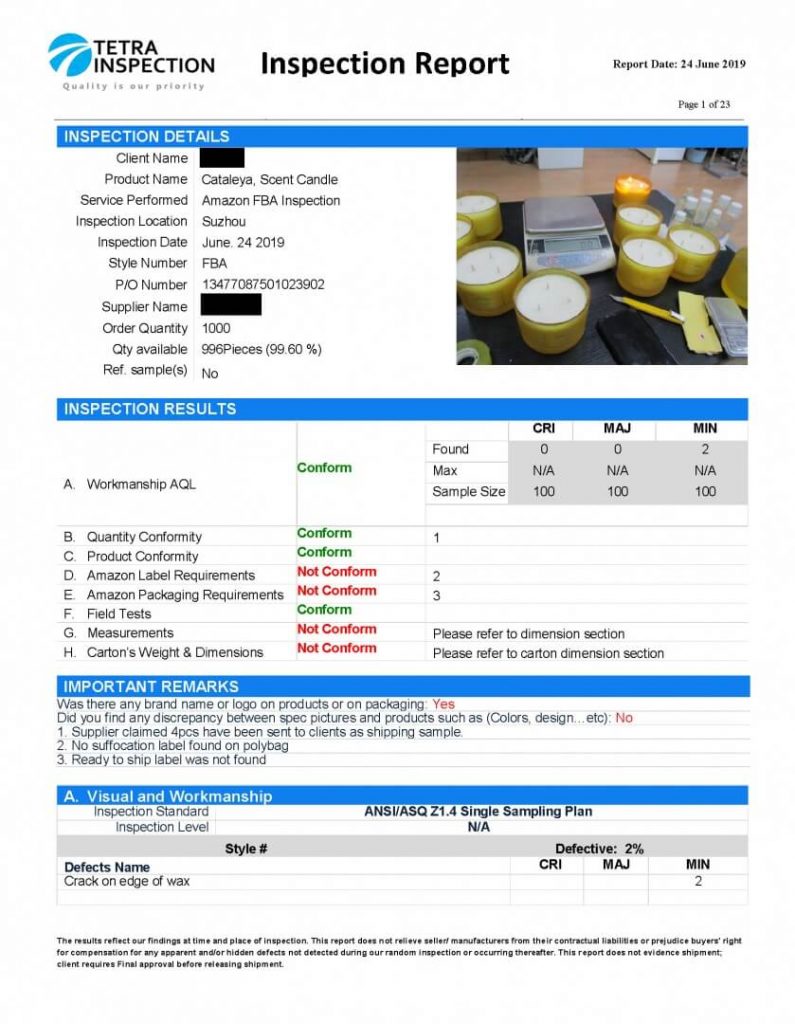

7. Inspection Report:

After performing several tests, the inspector prepares a detailed report outlining all the findings, insights and recommendations. It should also contain evidence like images of the products inspected. Most quality inspection companies will provide you with the inspection report within 24-48 hours.

Why choose Tetra Inspection?

Tetra Inspection is a global quality inspection service provider operating in 40 countries in Asia, Africa and Europe. With a hands-on approach, we are trusted by renowned global brands and retailers to ensure that the products meet the highest quality standard, safety regulations and establish a zero-waste supply chain.

If you’re looking for reliable and flexible quality control services in China, get in touch with us today.

Conclusion:

Product quality inspection is an essential step to make sure your products are free from defects and compliant with safety and customs regulations. Hiring an accredited quality control partner in China can make your life easier by helping you improve the quality of future products, or take corrective action if necessary.