The current chip crisis has caused disruptions and shortages in the global supply chain, making it more important than ever for buyers to ensure that their suppliers are able to meet their needs. One way to do this is through the use of supplier verification audits.

But what are supplier verification audits, and how can they aid buyers during this chip crisis?

Supplier verification audits are a process in which a buyer assesses the capabilities and practices of their suppliers to confirm that they meet the buyer’s requirements. This can include evaluating the supplier’s quality management systems, production processes, delivery schedules, and other important factors. The audit process may involve on-site inspections, reviews of documentation, and interviews with supplier personnel.

Conducting a supplier verification audit can provide a number of benefits to buyers during the current chip crisis. First and foremost, it can help buyers confirm that their suppliers are able to meet their needs in terms of quality, delivery, and other important factors. This is especially important during times of high demand, as shortages and disruptions in the supply chain can make it difficult for buyers to secure the chips they need. By conducting a supplier verification audit, buyers can have greater confidence that their suppliers will be able to deliver the necessary chips in a timely manner and to the required quality standards.

In addition to confirming that suppliers are capable of meeting the buyer’s requirements, supplier verification audits can also help buyers identify any potential issues that may arise in the supply chain. For example, if a supplier is experiencing production delays or quality control issues, a supplier verification audit can help the buyer to identify these problems and take steps to address them. This can help buyers to proactively manage their supply chain and avoid potential disruptions or delays.

Supplier verification audits can also help buyers to mitigate risk by providing them with a better understanding of their suppliers and their capabilities. By conducting a thorough assessment of their suppliers, buyers can make more informed decisions about where to source their chips and can better plan for potential disruptions in the supply chain. This can help buyers to ensure that they have a stable and reliable source of chips, even during times of high demand and potential shortages.

In conclusion, supplier verification audits are a valuable tool for buyers looking to ensure a stable and reliable supply chain during the current chip crisis. By confirming that their suppliers are able to meet their requirements and identifying potential issues, buyers can mitigate risk and secure the chips they need to meet their own demand. By focusing on these important keywords, buyers can ensure that they are well-equipped to navigate the challenges of the current chip crisis and secure a stable supply chain.

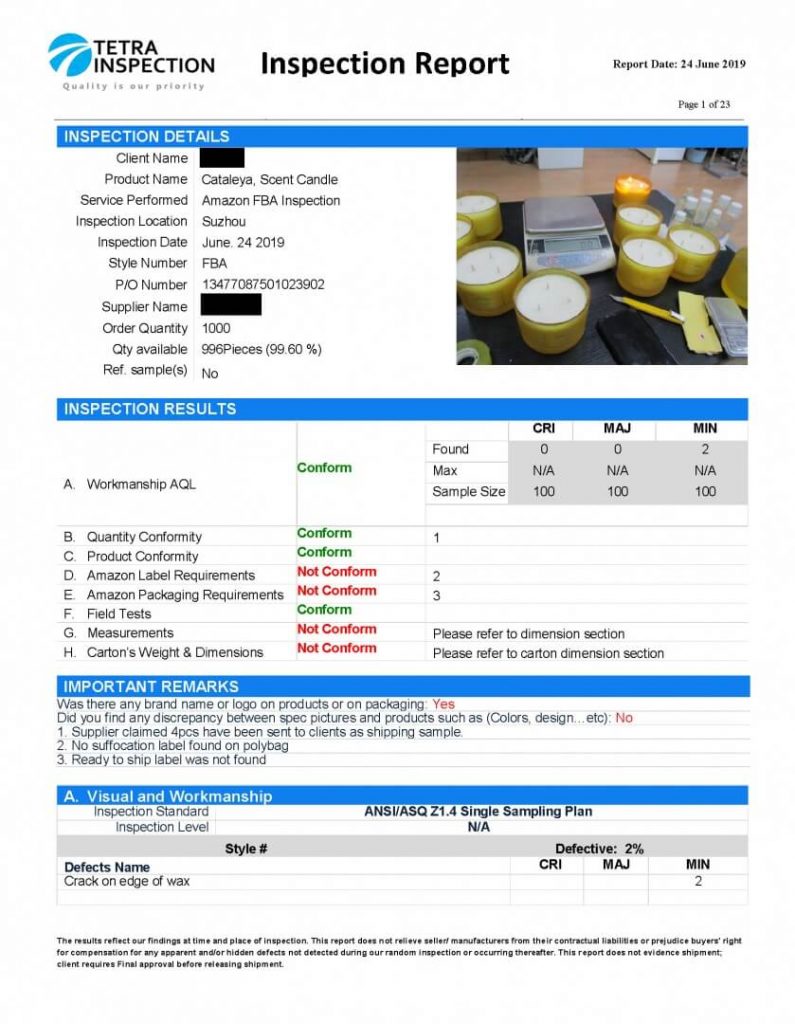

Download a sample report

Fill in the form below to download a sample report of your choice